Key benefits

- Stable emulsion

- Products with particles

- High viscosity products

- Noise <78 dB(a)

- Low utility consumption

- Hygienic design

- Ease of maintenance

- CAPEX & OPEX optimised

- EHEDG, EC 1935 and CE marked

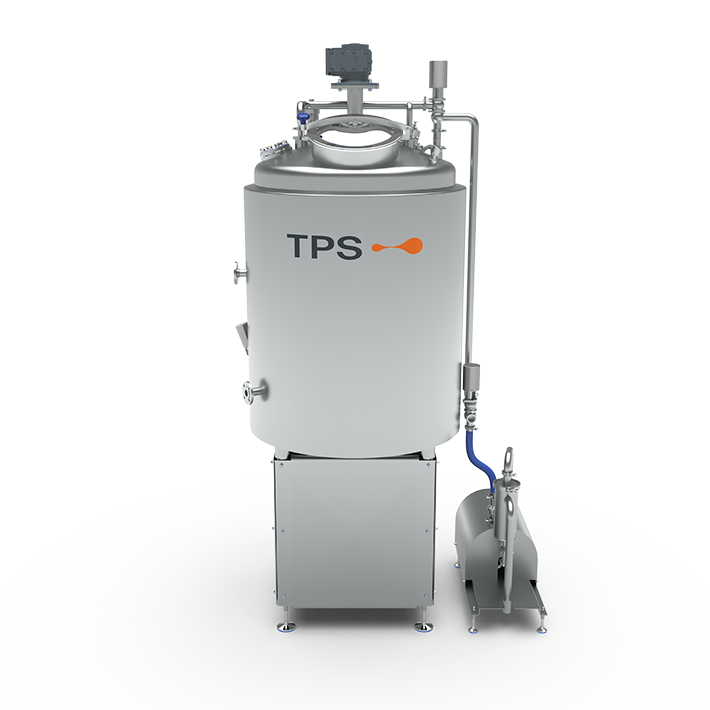

Equipment details

Design

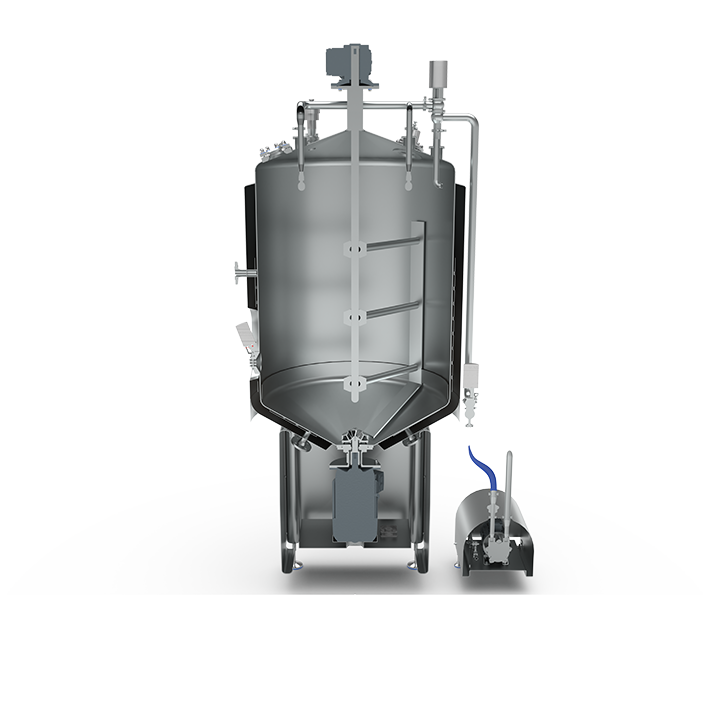

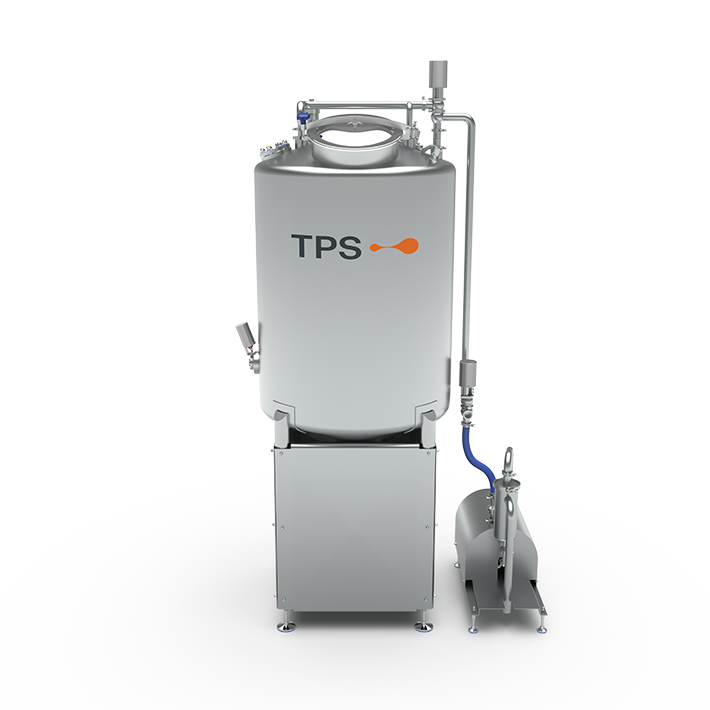

Designed in Denmark according to EHEDG, EC 1935 (food contact materials) and CE marked. The MixSing Process high shear mixer is designed as a cost-effective high shear mixer solution for high viscosity recombined homogenous products with or without particles. High viscosity products can be pumped with a lobe pump.

The mixer is designed with jacket heating or cooling, with the option of direct steam injection and flash cooling.

A scrape agitator provides efficient cleaning of the tank wall as well as further mixing of the product. The scrape agitator system is designed without any loose parts inside the tank and is provided with high quality peek materials for the scraper blades. The PEEK material can withstand high temperatures and is resistant to CIP chemicals. The blades can be supplied in blue colour material which is metal detectable.

Further, designed for adding a bin lifter system when producing products with particles.

The mixer is designed for pneumatical dosing of powders below the liquid surface by the vacuum system. This allows for handling of powders in a separate, dry room.

The vacuum system on the mixer lowers the amount of incorporated air in the final product.

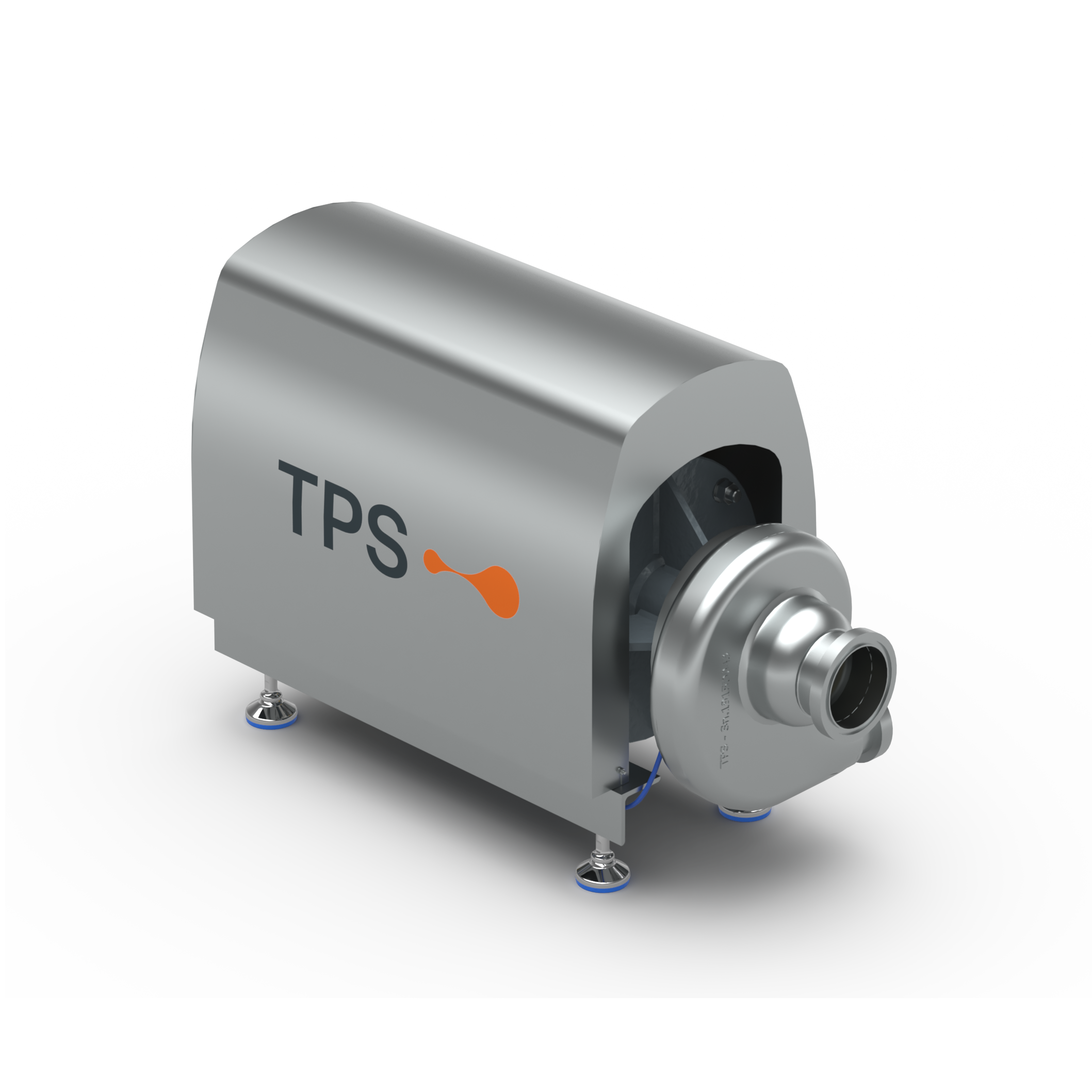

Using the latest CFD technologies and 3D design tools, the mixer has been optimised to achieve low utility consumptions and noise emissions below 78 dB(a). A 160 mm diameter high shear unit tested on water at 2,600 rpm resulted in a 75 dB(a) noise emission. Further, material choice and strength have been evaluated and documented by Finite Element Analysis (FEA) and PV Elite®. Designed for full vacuum to +0.5 bar(g) pressure according to EN 13445 part 3 as a non certified pressure vessel

To achieve a cost effective service, the mixer is designed using available globally quality components from OEM suppliers. Brands can be adapted to local requirements.

Operation

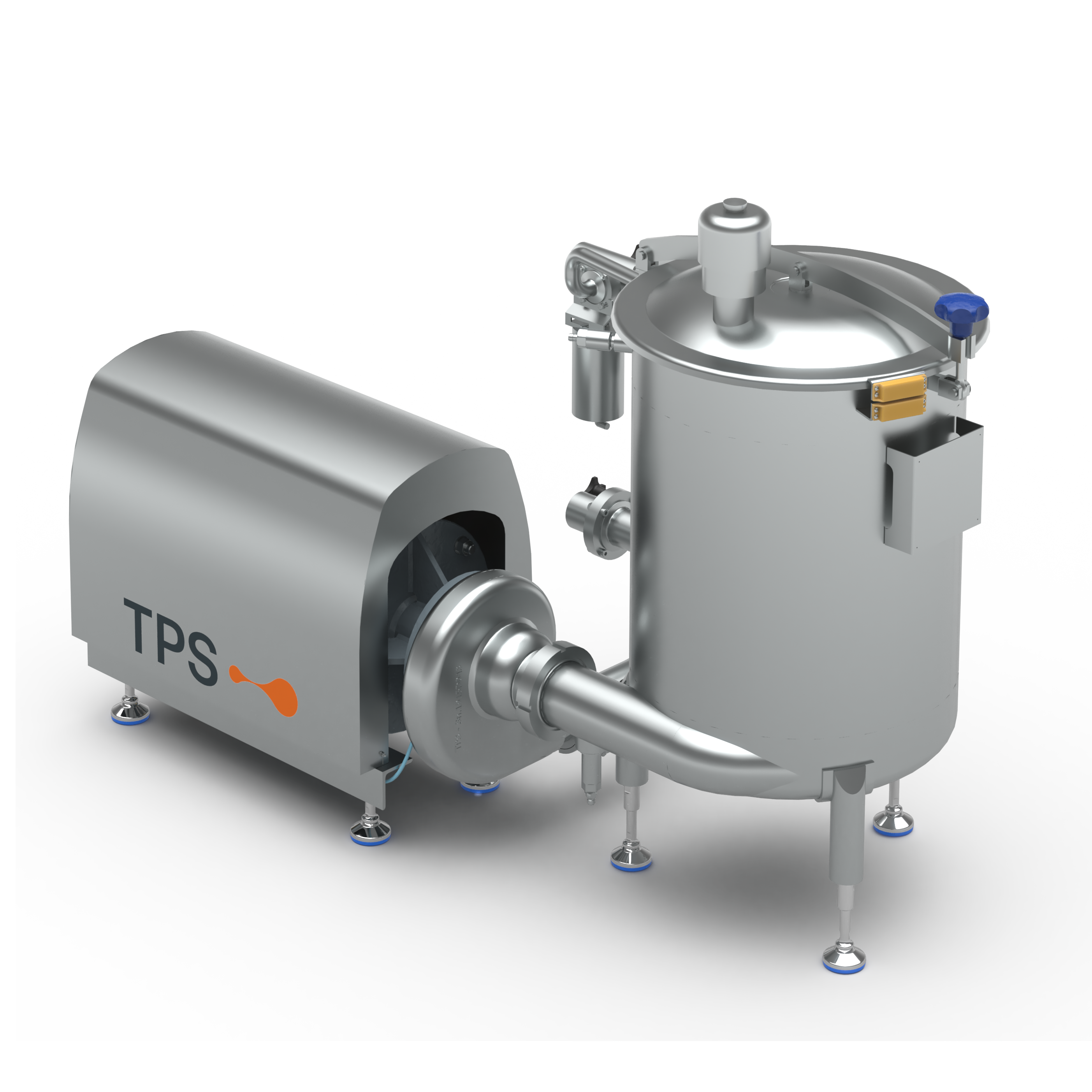

Pre-batching of powders takes place in a separate, dry room. From here, the powders are conveyed pneumatically into the mixer. In the high shear mixer, the particle size of the emulsion is reduced (homogenised) to create a stable emulsion. Minor speciality ingredients are added by separate and dedicated minor ingredients hoppers.

In the mixer a scrape agitator keeps the walls free of build ups. The scraper is used for high-viscosity products to keep the product in movement, the wall clean and to reduce the risk of burnt particles.

Larger particles can be dosed by using a bin lifter. The particles are homogeneously distributed in the tank by use of the high shear mixer and the scrape agitator.

For temperature adjustment of the product, the tank jacket can operate using steam, hot and cold water for the adjustment. Further, addition of direct culinary steam injection allows for fast and high temperature heating of the product.

A flash cooling system to cool the product in the tank can be installed.

The MixSing Process can be supplied both as batch, in-line (multi-pass system), or continuous (single-pass system) production mode.

Customisation

Fully flexible in design – although the MixSing Process is designed based on industry-leading experience – your customisation requirements can be incorporated. To the extreme, we can customise everything to accommodate your specific requirements (batch size, brands, materials, CIP etc.).

In the basis version, the MixSing Process is supplied without control system and MCC; however, upon request, can a fully standalone system can be designed and supplied.

Service

The MixSing Process mixer is designed for ease of maintenance by using globally available quality components from OEM suppliers, which means that service can be carried out by local teams. The extended height below the mixer system allows for a pallet jack to remove the motor and the high shear mixer unit.