Service

Our services for high shear mixers

At TPS, we understand the importance of a full circle of services. Our scope can include training, installation, and commissioning. Further, our team can carry out modifications, supply spare parts, and run product trials.

Our approach

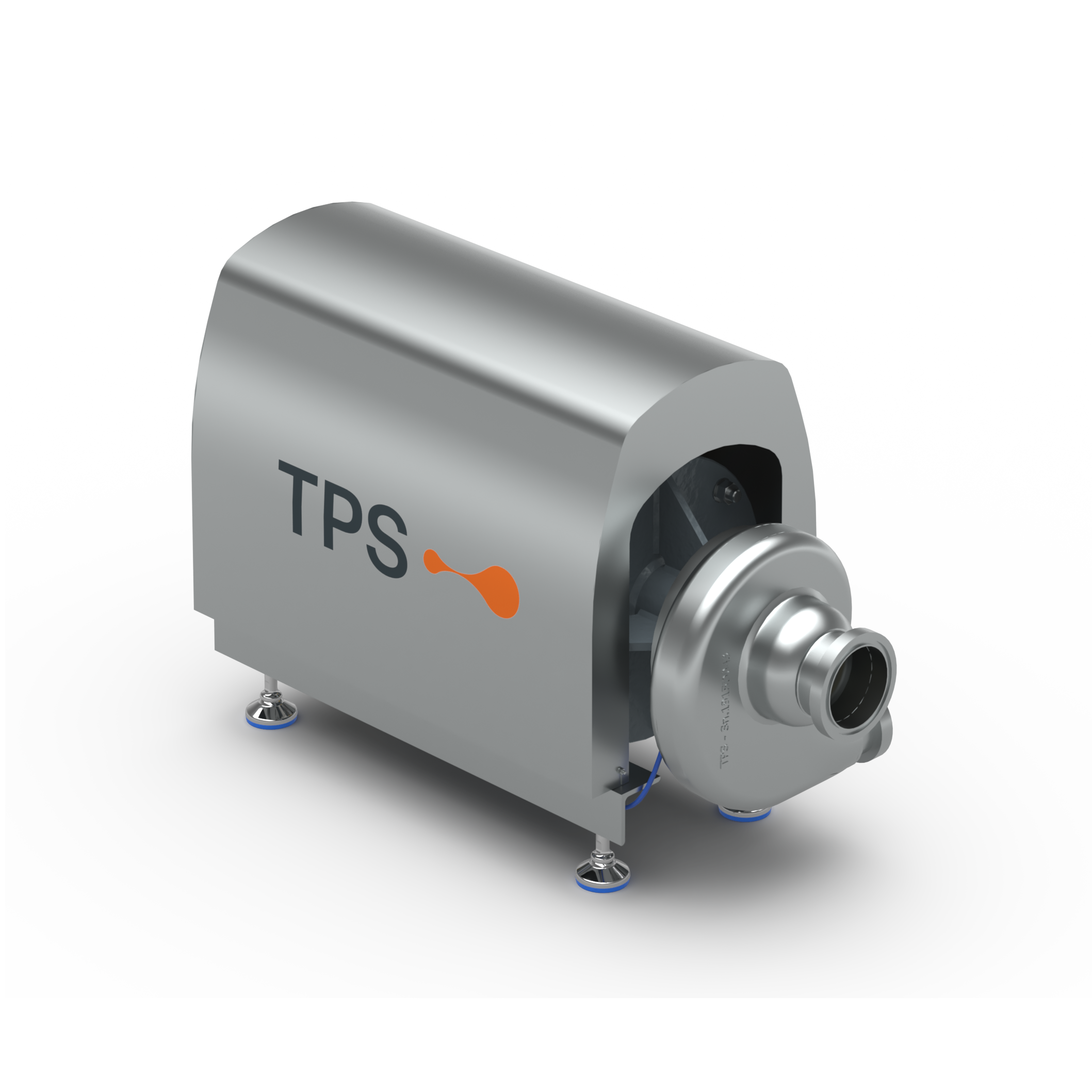

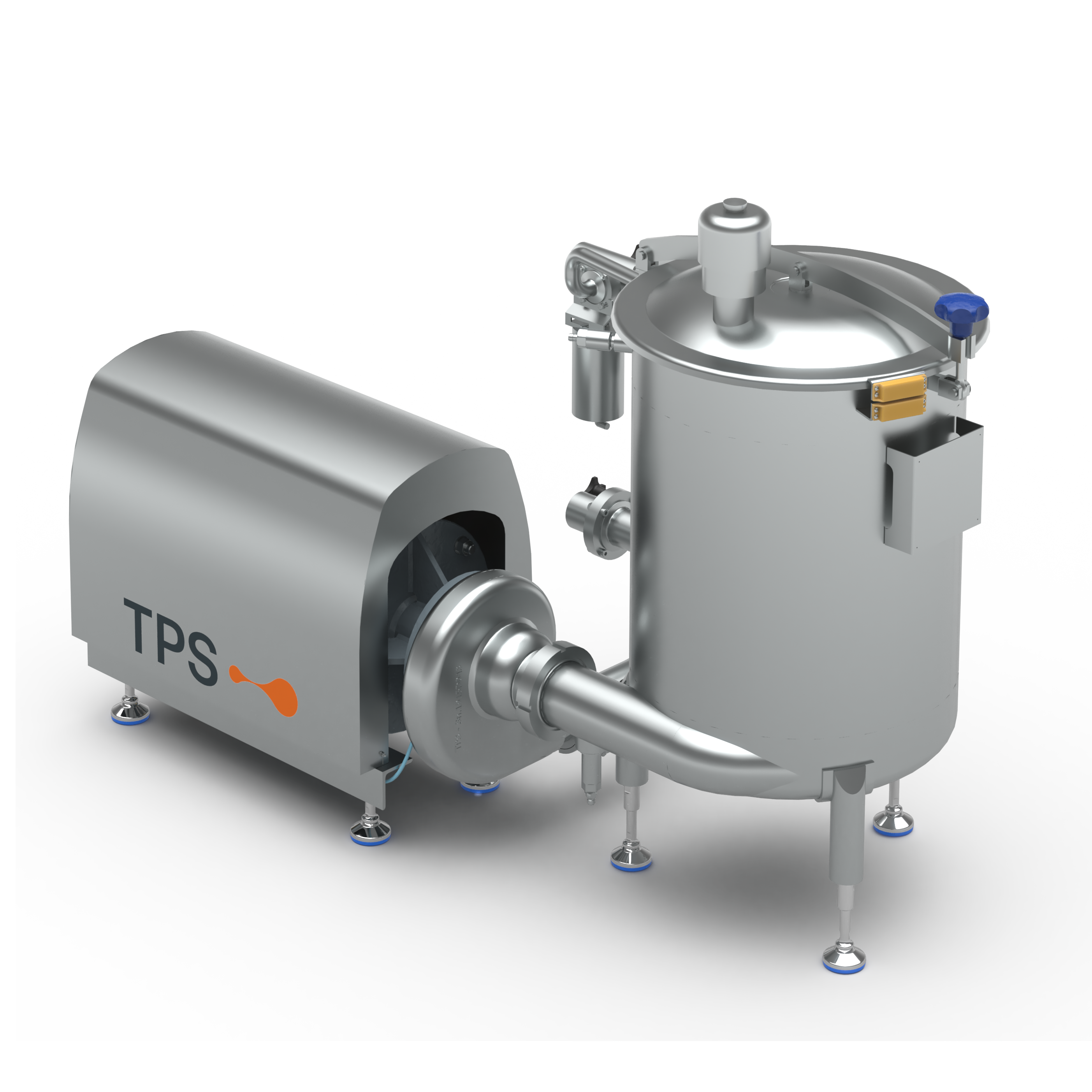

Generally, we choose to design for local support on service and spare parts by selecting components from global OEM suppliers. Further, our MixSing series of high shear mixers is designed with minimal service requirements and with few specially designed parts.

To service you better, we have a network of qualified servicemen for cost-effective and local availability.

Tailor-made solutions

When something special is required, we design the perfect fit for rebuilds or new plants. With the MixSing being designed in-house, we can make that special one-off for you, when required.

Extensive know-how

With an internal team with more than two centuries of industry experience, we understand the challenges in execution from rebuilds to greenfield sites.

Connected

We have built a broad network of industry specialists allowing us to pull on decades of industry experience in most dairy and beverage processing areas.

Training

Strengthening your team’s skills and knowledge

Walking blind and alone is not the way to success. TPS takes pride in ensuring our training sessions making the teams stronger, more knowledgeable, and more independent. Long-term profitability starts by learning a trade. Whether you are installing a new production facility or extending an existing one, proper training of teams is required.

TPS’s training programmes

On-ground: A tailored programme for operators, engineers, and managers with daily field activities. Takeaways ‘how to’ operate and maintain.

- Theoretical (web-based): A theoretical technology and application session setting the team apart from others.

- Refresher (web-based): At 12-months post-handover, get up to speed with the details you forgot from the on-ground session.

- On-ground: A tailored programme for operators, engineers, and managers with daily field activities.

Installation

Installation models for every need

Proper installation of the parts / process plant is key to optimal operation and longevity of the installation.

An installation team can consist of a helper, a fitter, and a welder each with their specific training. The welder is critical for the quality of the installation and shall have the necessary certifications to carry out the work.

TPS site team has a broad experience in all models and can be hired to evaluate capabilities of a local partner.

Civil work will not be part of TPS’ responsibility.

1. Supervision

TPS supervisor to oversee the installation and liaise with your hired resources. This is the most cost-efficient solution.

2. Installtion

TPS supervisor to lead TPS hired installation resources and work with your hired lifting crew/supervisors and cranes (machinery).

3. Installation+

TPS manages installation of the parts / process plant including installation teams and machinery.

Modifications

Line and equipment upgrade

In dialogue with your team, we review and evaluate the requirements to achieve the extra capabilities, more efficient CIP, fast change-over, handling of new ingredients etc. We setup an engineering team to take the project from design review to back in production. Services can include automation, installation, commissioning services (mechanical, product), and operator training.

Spare parts

High-quality spare parts that ensure uptime

Planning of maintenance and parts availability to minimise TCO. This is a task of your engineering team to ensure its resources are available and planned prior to an unscheduled breakdown.

TPS spare parts models

- Self-managed: As part of the delivery of your plant, a complete, detailed spare parts manual will be provided. A manual that allows you to proceed and procure directly from the OEM part suppliers.

- TPS-procure: Parts are procured at TPS prevailing rates, via TPS, upon enquiry from your team.

Innovation center

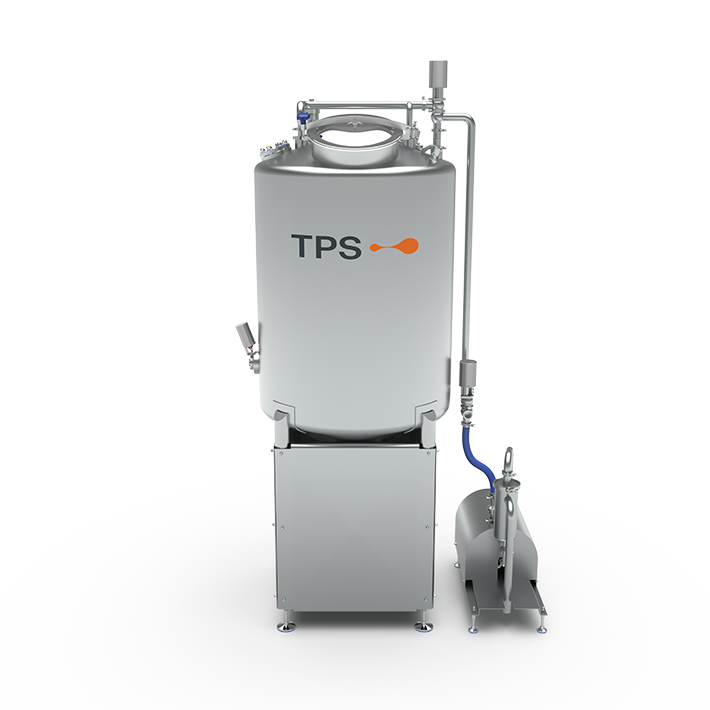

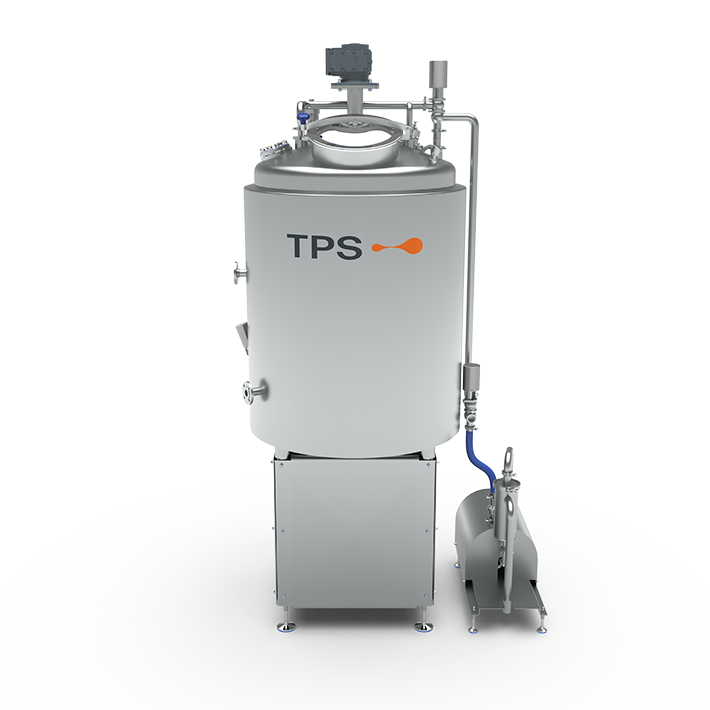

Testing is important to confirm mixing capabilities of your product and for this reason we have five mixing plants available in Denmark or for sending to your site. Our test plants include MixSing Shear, MixSing Standard, MixSing Vacuum, MixSing Process, and MixSing Pilot – our most versatile unit.

Based on our experience, the best test is conducted at your site. Here you have access to all your raw materials, you can run multiple tests, evaluate ease of use of the mixer, confirm the quality of the equipment, and analyse the product in your own laboratory and keep data safe.

Request service

Request for service from us and we will get back to you with an offer.

We are always ready to help

If you are looking for a specific application or type of equipment, reach out to us.

Explore our selection of high shear mixers

More from TPS

Applications

High shear mixer solution for a wide range of application and processes within dairy, food, beverage, and personal care.

Read more