Customer cases

Reaching great results in collaboration with clients

TPS strives to meet or exceed our customers’ expectations in our execution. Collaboration is essential for the success, and we do our utmost to create a good project work environment.

Process Plant

Brownfield process plant for the manufacturing of Greek yoghurt.

Client: Confidential

Place: Middel East

Period: Q1’2026

Application: Dairy

The project includes our MixSing Vacuum high-shear mixer, our latest MixSing FatMelt for melting butter blocks, and various fermentation and mixing tanks.

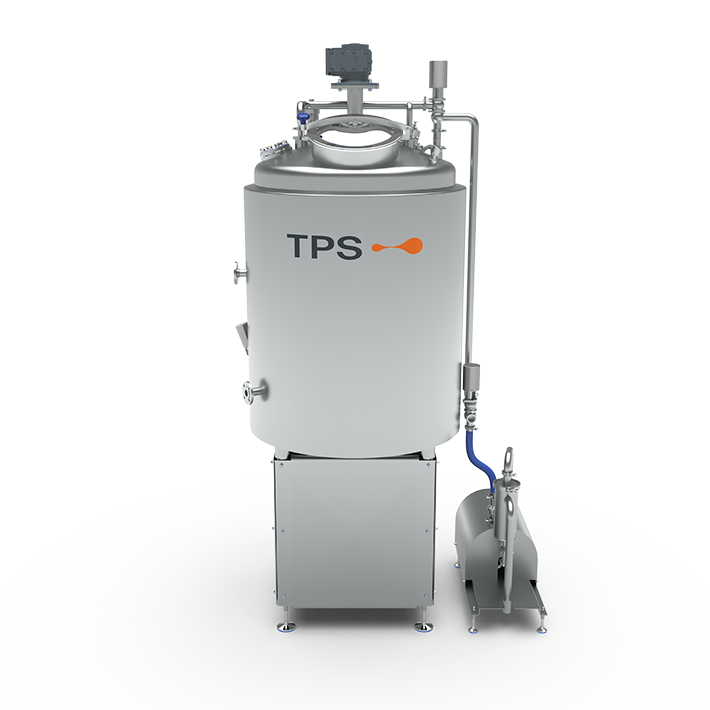

MixSing Vacuum in a recombination line

The MixSing Vacuum forms the backbone of a recombination line that also incorporates our latest MixSing Coaxial technology.

Client: Confidential

Place: Middel East

Period: Q4’2024

Application: Dairy

The recombination line, designed with the MixSing Vacuum, includes pasteurisers, homogenisers, various fermentation tanks, and our MixSing Coaxial, specially developed for the manufacturing of cottage cheese. The line also features several SKID units for hot water and cooling.

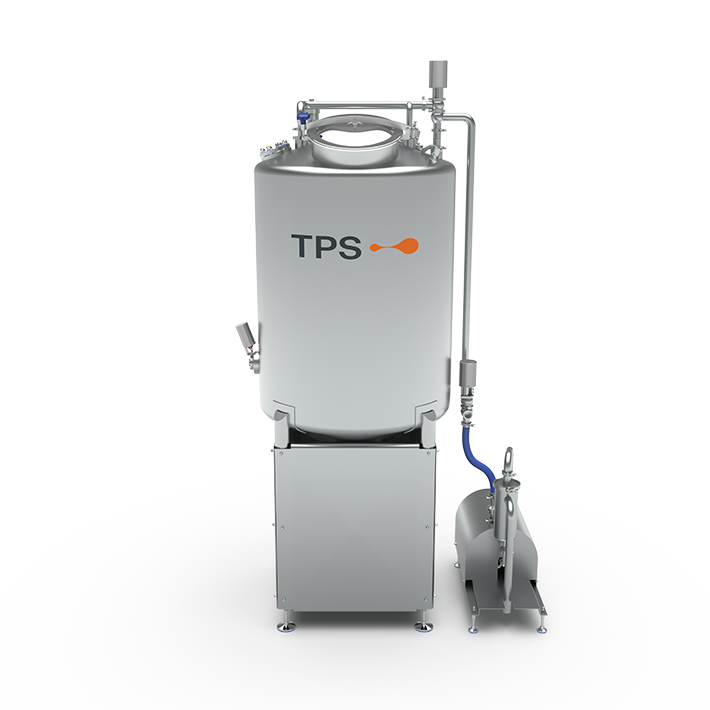

MixSing Vacuum for recombination

The MixSing Vacuum, equipped with our latest MixSing Wall Valve, eliminates dead legs in the butterfly valves installed on the tank. The design prioritises quality and stringent hygienic standards.

Client: Confidential

Place: Middel East

Period: Q2’2024

Application: Dairy

The MixSing Vacuum is installed within a larger batch tank system, enabling the recombination of larger powder quantities into the mix. Powders are conveyed via vacuum from a powder tipping station equipped with integrated filters, also provided by TPS. Branded sub-equipment and AISI 316L stainless steel for all product-contact parts ensure the durability and high quality of the system.

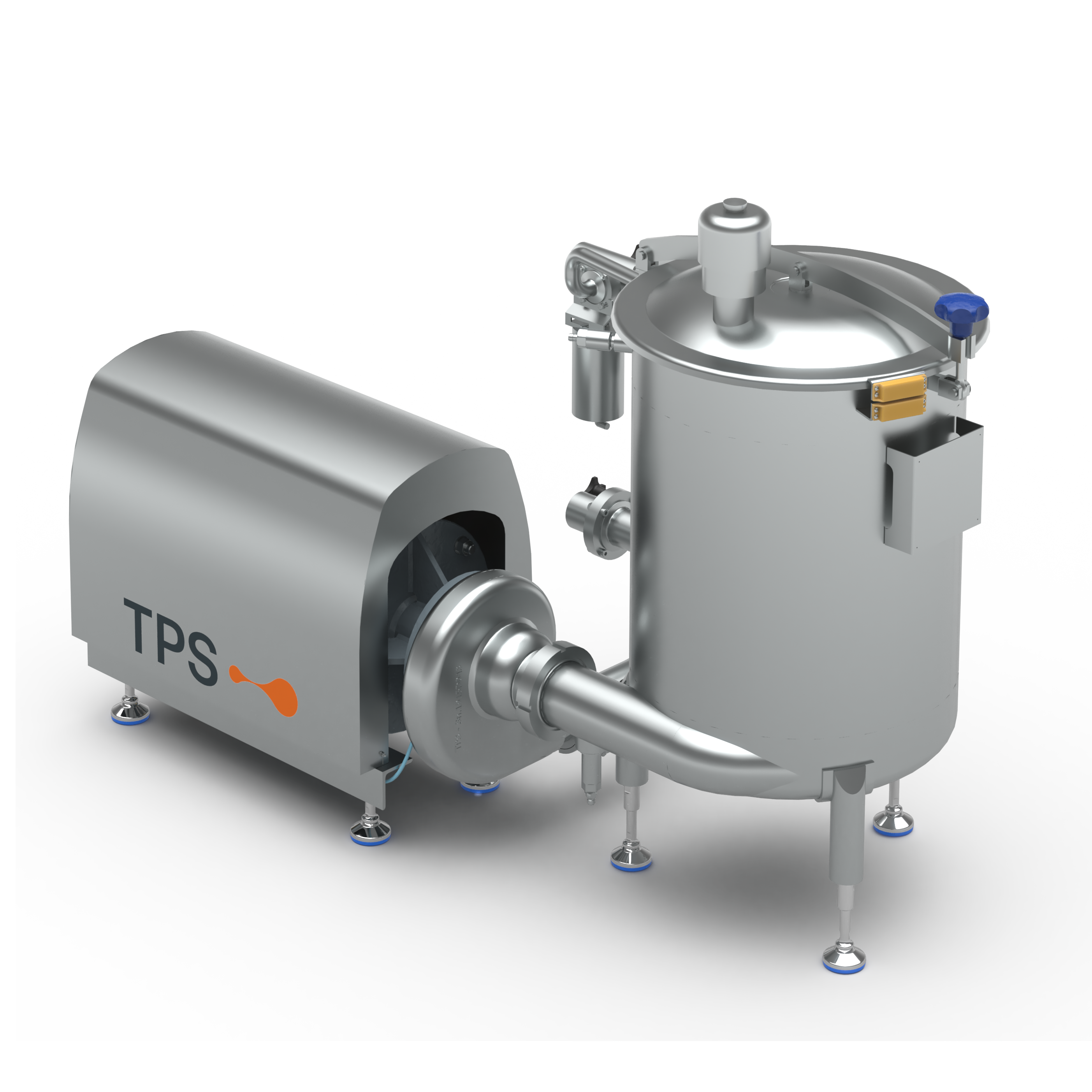

MixSing Vortex for mixing powders, liquid, and soft lumps

The MixSing Vortex includes a large 83-litre tank, a circulation system, and various instruments.

Client: Confidential

Place: Latin America

Period: Q4’2023

Application: Chemical

The MixSing Vortex is a versatile powder blender and mixer capable of combining powders, liquids, and soft particles in a single process. The MixSing Vortex can handle high flow rates and manage up to 200 kg/min powder. Plus, with its discharge pressure exceeding 2 bars, there’s no need for an additional downstream pump.

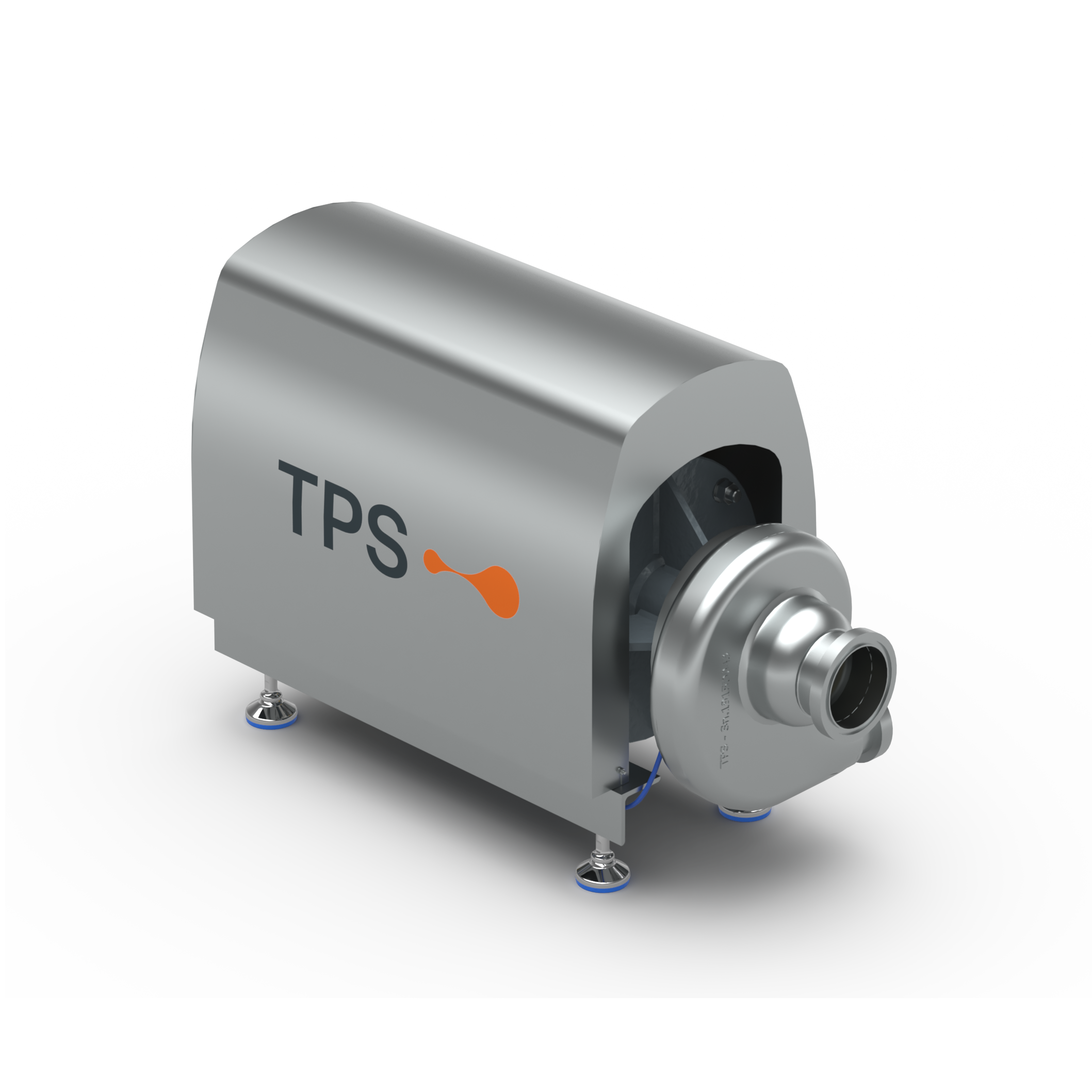

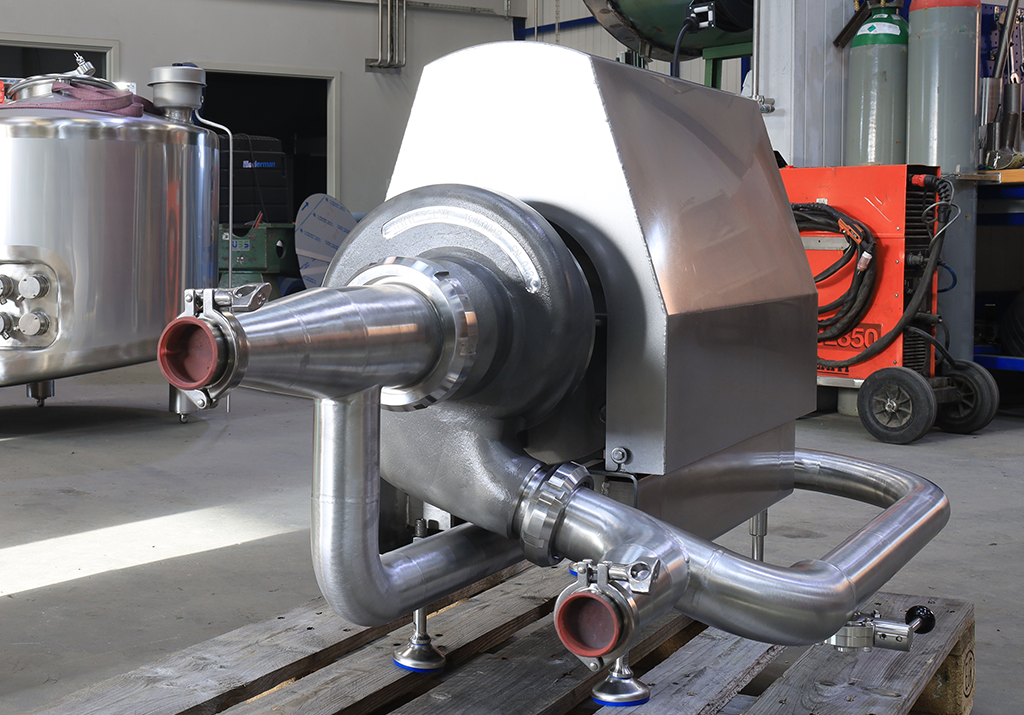

MixSing Shear Loop for emulsification

The MixSing Loop, with its 200,000 s-1 in shear rates, is uniquely positioned to emulsify various applications. Here, it includes a frequency converter and a manual control system.

Client: Confidential

Place: South Africa

Period: Q3’2023

Application: Food

The MixSing Shear Loop is an efficient powder blender, perfect for homogenisation or emulsifying materials between silos or circulating them across multiple storage units. With a discharge pressure of over 2 bars, there’s no need for an additional downstream pump. Not only is the MixSing Shear Loop engineered for rapid batch processing, but its durable design also lives up to its impressive appearance.

MixSing Injector for mixing powders and liquid

This fully specked MixSing Injector includes a table, a large 73-litre funnel, an injector system, a frequency converter and a manual control system.

Client: Confidential

Place: South-East Asia

Period: Q2’2023

Application: Beverage

MixSing Injector function as a powder blender or powder mixer and can be connected to single or multiple silos. With the customisable capacity, it can have very high flow rates and powder amounts of up to 100 kg/min for skimmed milk powder. The > 2 bar discharge pressure saves you the downstream pump.

MixSing Shear for homogenisation

The MixSing Shear, with its 200,000 s-1 in shear rates, is uniquely positioned to homogenise fruits and vegetables and create perfect smoothies.

Client: Confidential

Place: Europe

Period: Q1’2023

Application: Smoothies

MixSing Shear is a powerful powder blender or powder mixer to homogenise or emulsify your application between silos or in circulation over multiple silos. The > 2 bar discharge pressure saves you the downstream pump.

It’s built to last, as the looks pretend.

MixSing Shear Loop for cutting fibres

The MixSing Shear Loop is designed to cut vegetable fibres in juice. The impeller and stator system custom-made for the application ensures smooth and continuous operation.

Client: Confidential

Place: Latin America

Period: Q1’2023

Application: Juice

MixSing Shear Loop is designed to increase the homogenisation effect over the MixSing Shear.

The > 2 bar discharge pressure saves you the downstream pump.

It’s built to last, as the looks pretend.

Adding Liquid Design Capabilities to Powder Handling Technology Company

“A global dairy and food producer had issued a tender for a large powder handling system in Malaysia. A requirement for us as the winning bidder was a process turnkey solution. For the liquid design, we found TPS’ approach, design and solution fulfilling our requirements.” William Tan, Head of Sales APAC, Swiss Company for Powder Handling.

The system consists of several lines handling high-viscosity liquids and includes, e.g. tanks, pumps, valves, hot water jacket pipes, and specially designed agitators.

Helping Create Scalability for a US Engineered Equipment Supplier

“The high technical competence created by partnering with TPS allowed Caloris to augment our staff and scale quickly into new projects while maintaining the high standards and quality of our product. The reliability, adaptability and responsiveness of TPS were outstanding. TPS took the strategic view that our success was their success.” Jim Kent, Business Development Manager, Caloris Engineering LLC.

A 6 months engagement to add competent equipment design and drafting staff will become a multi-year relationship, as TPS was able to make available staff with the industry-specific experience needed.

Contact us

If you are looking for a specific application or type of equipment reach out to us – we are always ready to help.